Thermal Heat Treating

Thermal heat treating is performed at American Handforge on all products with precision and controls necessary to produce wrought products meeting the most stringent industry standards.

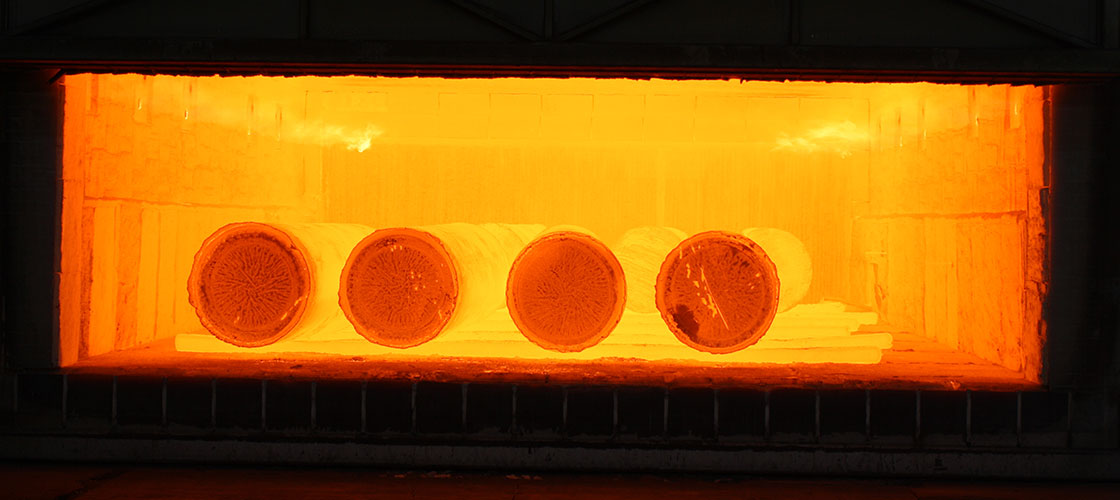

Initially the metal forge stock is heated to the prescribed forging temperature range in calibrated and surveyed furnaces.During forging, the temperature requirements are carefully controlled, not only of the stock, but the die temperatures as well.

By this close monitoring, adherence to metallurgical operating practices is assured. This means consistent quality products are being made and variability is minimized. Individual records of these forging temperatures are maintained and routinely reviewed by quality assurance.

State-of-the-Art Facilities

Solution heat treating or any thermal process required to achieve the ordered temper or condition is performed in well designed and modern qualified furnaces. Quench facilities for aluminum are located on tracked wheeled large tanks, and are capable of adjusting to the requirements for cold, warm, or hot water medium. Large circulating water pumps assure thorough agitation of the bath at the designated quench temperature to assure uniformity during quench.

Furnace temperature and load tracking to established practices is performed using multiple thermocouples and results are operator verified, logged, and filed. Aluminum heat treating in general is performed to the requirements of AMS 2772 for raw material.

NADCAP Certification

In addition, we conform and carry certification to Nadcap thermal process requirements. This certification requires regular furnace uniformity surveys, system accuracy testing, and the adherence to written procedures which maintains compliance to quality assurance standards to quality assurance standards and with Nadcap policy. Records of all heat treating and thermal processes are logged and maintained for review when necessary.

Artificial aging, when the ordered temper requirement calls for a "T" temper, for example, T6 or T74, is similarly performed in lower temperature aging furnaces. Complete records of all aging or thermal processing are logged, reviewed and maintained. Heat treat operators are well trained and are skilled in performing their craft. Photographic records are made of each furnace load with regard to racking for both solution heat treat and artificial aging. Reviews of those records are made by quality assurance on a regular surveillance basis. Material not meeting initial acceptance standards is quarantined and submitted to metallurgy for their review.

Inspection & Testing

Inspection by the heat treat operators where applicable, is performed on the surface for hardness. Surface conductivity for those products that are generally classed as –T7 XXX type final tempers is performed. For other tempers, hardness is generally checked to assure that proper heat treating has been accomplished.

Following the completed thermal processing, which develops the ordered temper or condition; test samples are cut from the parent material and submitted to the Test Laboratory for acceptance and lot releasing. The tensile testing is performed at specified locations either from the drawing or ordered material specification. Sub-surface conductivity is determined for the –T7 type tempers.

In addition, duplicate hardness tests for most materials are performed under laboratory conditions. To assure strict quality assurance in the –T7 type tempers, actual specimens are selected on a surveillance basis for testing with alternate immersion stress corrosion specimens (ASTM-G47) and records maintained.

Heat Treating Provides Consistent Quality Material

As illustrated and described, precision heat treating at American Handforge yields consistent quality material. This is verified by laboratory testing of the final product to your ordered material specification and drawing requirements. Submit your special or custom requirements either in a drawing, sketch or description to our engineers.